Insights & Innovations from Evan’s Tool & Die

How To Find the Right Tool and Die Maker

Click to Expand Tool and die makers are some of the most skilled workers in precision manufacturing; they craft tools and metal forms needed for stamping and other forging operations. The work of a tool and die maker entails analyzing design specifications, cutting and shaping metal, assembling parts, and testing completed products for use in […]

> Read Full StoryUnderstanding Tool And Die Engineering And Manufacturing

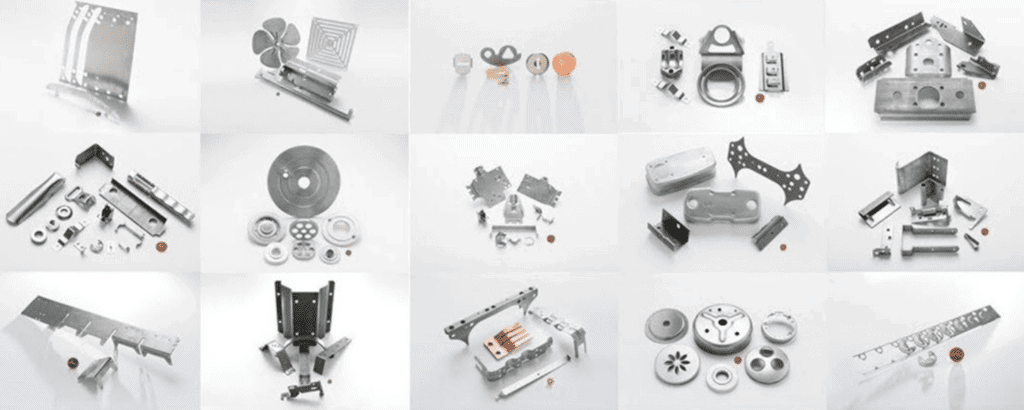

Click to Expand Tools and dies are essential to the manufacturing industry; without these, cutting, forming, or shaping metals would be unthinkable. A tool-and-die business can help other companies manufacture and innovate products for various industries, from automotive parts, to medical components, to everyday household items. Some machinists and tool and die makers use computer-aided […]

> Read Full StoryHow To Choose a Tool and Die Shop

Click to Expand The tool and die industry allows people to innovate and make custom parts for the automotive, technology, and aeronautic industries. Tool and die shops are responsible for fabricating dies, molds, and tooling using specialized cutting technology. They help manufacturers and customers create durable and complex machine tools, cementing their spot as key […]

> Read Full StoryWhy The Tool and Die Process Is Important in All Metal Working

Tool and Die is a process of making custom metal parts. It involves using specialized tools and dies to cut and shape the metal into the desired form. Tool and die can be used for a variety of purposes, from creating small parts to fabricating large components. The process of Tool and Die begins with […]

> Read Full StoryBenefits of Modern Progressive Metal Stamping and Hand Transfer Stamping in Manufacturing

Metal stamping is a type of metal working that has been around for decades. It involves shaping various metals into specific shapes or parts through multiple stages of compressive deformation. The stamping process works by applying an external force over a single work piece or metal sheet which can be made up of different alloys, […]

> Read Full StoryTop Benefits of Local Sourcing

Consumer landscapes are continuing to change while businesses are adjusting for the new normal. Manufacturers and industrial companies across the world are working hard to maintain and strengthen their supply chains. And companies who preferred to source internationally to save on costs, are seeking other cost-effective solutions. The growing reality is that procurement professionals actually […]

> Read Full StoryWelcome Roy Zeh, Evans VP of Business Development

We are proud to officially announce the arrival of the new Vice President of Business Development to Evans Tool & Die / Evans Metal Stamping. Roy Zeh is a veteran of the steel and manufacturing industries, and we are very excited to have his sales and marketing leadership at Evans. Here’s a recent interview with […]

> Read Full StoryHow the Toolmaker Apprentice Program has Changed in 50 Years

This article is the second installment of three articles about Toolmaker Apprenticeships. In the first article, we discussed the basic structure, time, requirements, and expected outcome from an individual’s journey through an apprenticeship. In this post, we’re taking a deeper look at how a Toolmaker Apprenticeship has changed since the 1970s. What has changed? To […]

> Read Full StoryThe Modern Day Toolmaker Apprentice Program

In this three part series, we examine the age old approach to job training called the apprenticeship. Through interviews with Toolmakers, Master Toolmakers, current and recent apprentices, we discover what it means to be a Toolmaker Apprentice today and what has changed in the last generation of Toolmakers. What is an Apprenticeship? Wikipedia provides a […]

> Read Full StoryStamping out a Robotic Surgical Instrument

In 2012, Evans Tool & Die Shop Supervisor Dick Ankeny was tasked with building a die for one specific part of a robotic surgical instrument. The specifications for the part required tolerances to be within .005”. The part had to be made from stainless steel, because the part itself would actually be inserted into surgical […]

> Read Full Story