Why The Tool and Die Process Is Important in All Metal Working

Tool and Die is a process of making custom metal parts. It involves using specialized tools and dies to cut and shape the metal into the desired form. Tool and die can be used for a variety of purposes, from creating small parts to fabricating large components.

The process of Tool and Die begins with a design. The design is then transferred to a computer, which will create a simulation of how the part will be machined. This allows for greater accuracy and eliminates the need for trial and error.

Creating Specialized Tooling

The next step is to create the tooling. Tooling is made up of the tools and dies that will be used to cut and shape the metal. The tooling is specifically designed for the part that is being manufactured and must be precise in order to create the desired outcome.

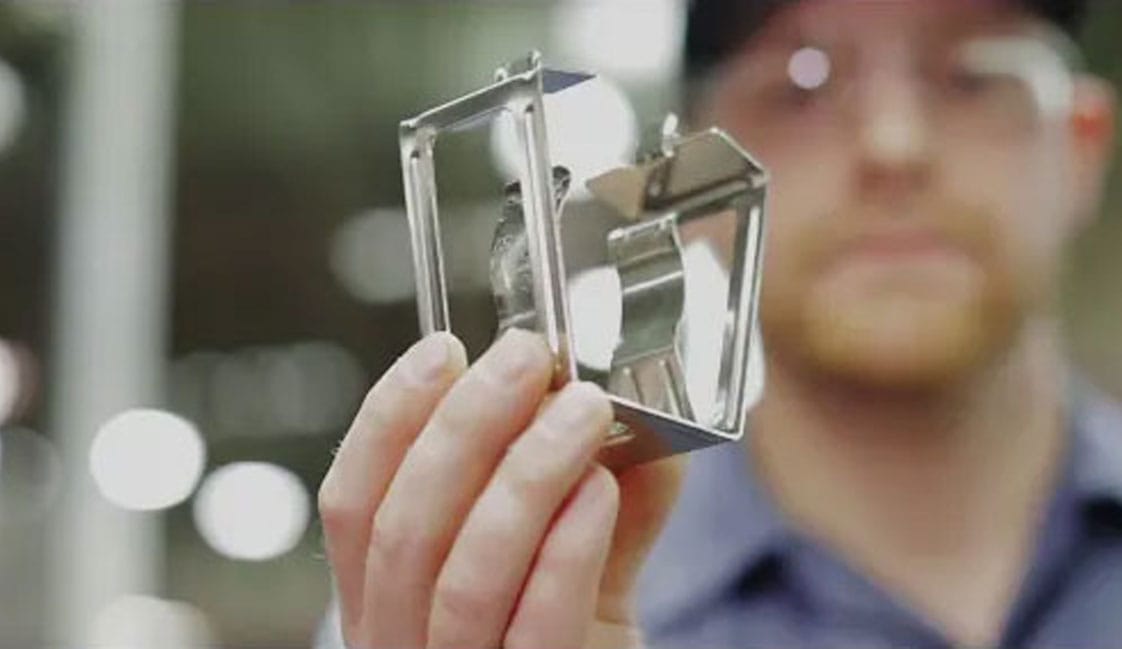

Once the tooling is created, it is used to cut and shape the metal into the desired form. The metal is then sometimes welded and finished as needed.

Design Engineering and Custom Metal Stamping

Design Engineering is the process of designing and creating custom metal parts. Design Engineering is a specialized process that requires a high level of precision and accuracy. When it comes to creating custom metal parts, Design Engineering is the process of choice.

Custom metal stamping , machining, welding and finishing are all part of the Tool and Die process. When it comes to creating custom metal parts, Tool and Die is the process where it all begins.

Metal stamping is the process of using a press to stamp metal into a desired shape. Metal stamping is a common manufacturing process that is used to create a variety of parts. Metal stamping can be used to create parts for a wide range of applications.

Tool makers in the tool and die industry create the dies, molds, machine tools, cutting tools, and other tools used in manufacturing. Tool makers are essential to the manufacturing industry and at Evans our senior tool makers are highly trained and have years of on the job experience.

Welding and Finishing Metal Components and Parts

In Tool and Die, ‘welding’ is the process of joining two pieces of metal together. Welding is a common manufacturing process that is used to create a variety of parts. It is an essential process in the manufacturing industry and provides a high level of precision and accuracy. Welding can be used to create parts for a wide range of applications.

In Tool and Die, ‘finishing’ is the process of polishing or cleaning metal parts. Finishing is a common manufacturing process that is used to put the finishing touches on the manufactured parts. It is an essential process in the manufacturing industry and provides a high level of precision and accuracy. Finishing can be used to create parts for a wide range of applications.

One Stop Tool and Die Shop

At Evans Tool & Die, Inc and Evans Metal Stamping, Inc. we’ve been a one stop shop since 1948. We have the capability to perform all the various services discussed in this article with precision, speed and care. Contact us today to get a free and fast quote to get started with your next tool and die project.

As a certified SBA – Woman Owned Small Business, we keep the entire process in-house. From concept, to design, to creation, packaging and shipping… we remove the need for 3rd party involvement. This ensures your project will be done to the highest quality standards and completed on time and on budget. With Evans, there won’t be any issues with supply chain delays as we handle everything ourselves.