Capabilities

About Our Capabilities

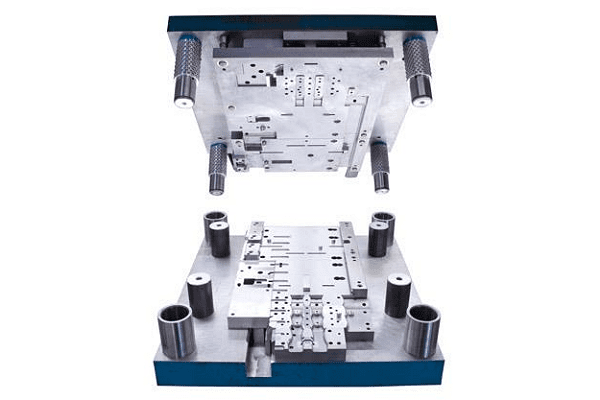

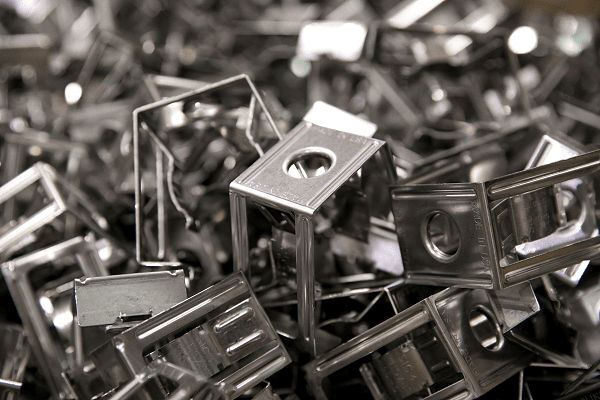

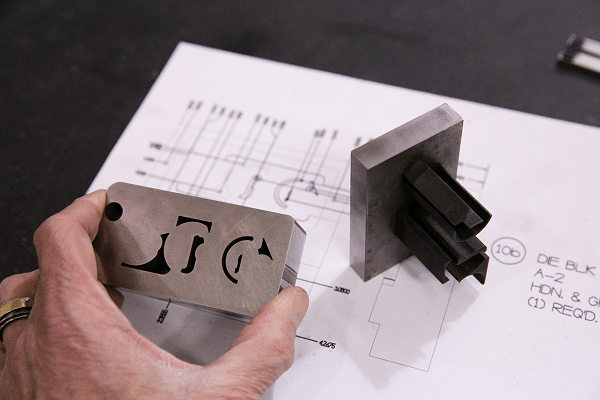

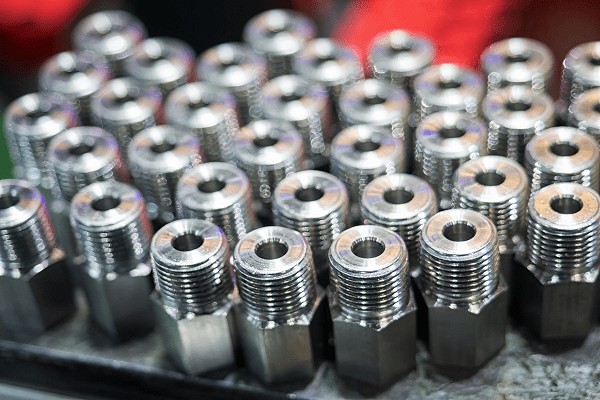

Since 1948, Evans Tool & Die has been a leader in tool and die builds, hand transfer, and progressive metal stamping solutions. Our products are 100% American-made and precision-crafted according to your specifications. In an era of heightened supply chain volatility, we enable OEMs to minimize risk and disruptions with localized sourcing and reliable logistics. As a one-stop shop, we provide everything from expert design and engineering services to assembly and packaging.

Below, you can learn more about our capabilities and the industries we serve.