Laser Cutting Services

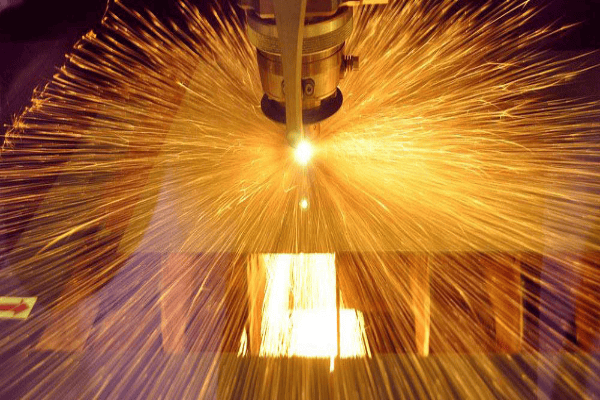

Laser cutting uses highly concentrated beams of coherent light that quickly and accurately cut very dense materials. The cutting action is actually a rapid thermal separation (i.e. melting) of the material. This results in minimal loss of material, so laser cutting is a highly efficient and precise alternative to other conventional cutting techniques. It also makes more intricate parts while reducing the need for finishing processes along the separated edge.

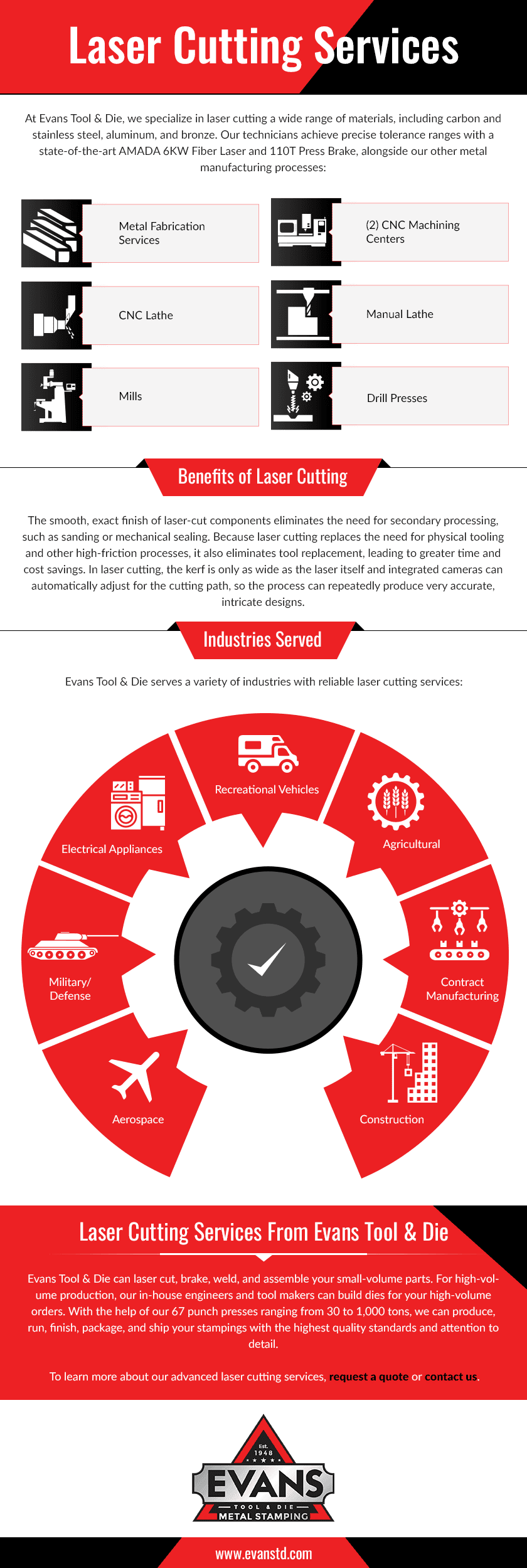

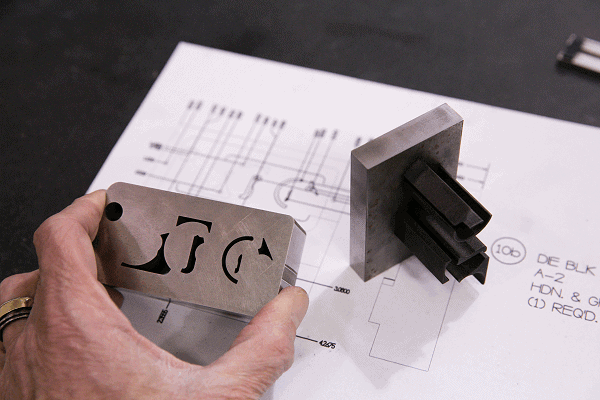

At Evans Tool & Die, we specialize in laser cutting a wide range of materials, including carbon and stainless steel, aluminum, and bronze. Our technicians achieve precise tolerance ranges with a state-of-the-art AMADA 6KW Fiber Laser and 110T Press Brake, alongside our other metal manufacturing processes:

- Metal Fabrication Services

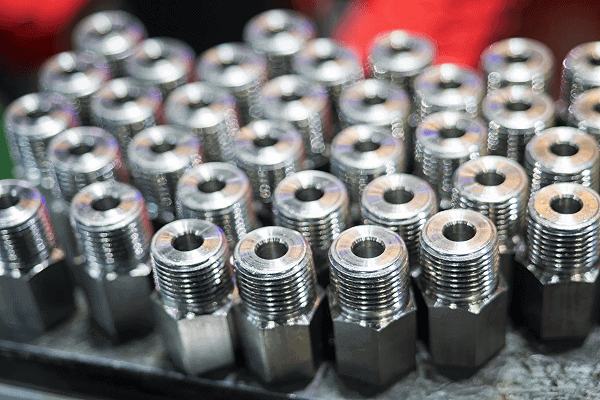

- (2) CNC Machining Centers

- CNC Lathe

- Manual Lathe

- Mills

- Drill Presses

Benefits of Laser Cutting

The smooth, exact finish of laser-cut components eliminates the need for secondary processing, such as sanding or mechanical sealing. Because laser cutting replaces the need for physical tooling and other high-friction processes, it also eliminates tool replacement, leading to greater time and cost savings. In laser cutting, the kerf is only as wide as the laser itself and integrated cameras can automatically adjust for the cutting path, so the process can repeatedly produce very accurate, intricate designs.

Industries Served

Evans Tool & Die serves a variety of industries with reliable laser cutting services:

- Aerospace: The aerospace industry requires components and products made with the highest quality fabrication standards. Evans Tool & Die consistently meets the tightest tolerance windows required for the rigors of space and high-altitude travel.

- Military/Defense: Military-grade electronics and other metal parts require advanced, fail-safe components built for heavy-duty use. Our laser cutting services consistently meet these demands.

- Electrical Appliances: As electrical components continually decrease in size, electronics manufacturers seek the most precise cutting technologies. Laser cutting metal accommodates more parts per material sheet, reducing waste and raising cost-efficiency.

- Recreational Vehicles: The automotive industry heavily depends on parts consistency. Metal laser cutting is ideal for its high repeatability and precision, including during mass production runs.

- Agricultural: From heavy machinery to storage and processing equipment, the agricultural industry requires high volumes of flat, complex parts to be joined by fasteners or welding. Laser cutting leaves smooth, even surfaces that require little or no finishing and are perfect for welding. The result is ready-to-assemble metal components almost right off the manufacturing line.

- Contract Manufacturing: Laser cutting is ideal for contract manufacturing, which makes continuous use of the laser cutting equipment and provides a return on initial investment over time. Our AMADA fiber laser cutting technologies provide fast turnarounds for our contract manufacturing customers.

- Construction: Large structural elements require highly consistent manufacturing processes, as any defect could result in structural flaws. Laser cutting metal is the most reliable method for achieving uniform parts for general construction purposes at scale.

Laser Cutting Services From Evans Tool & Die

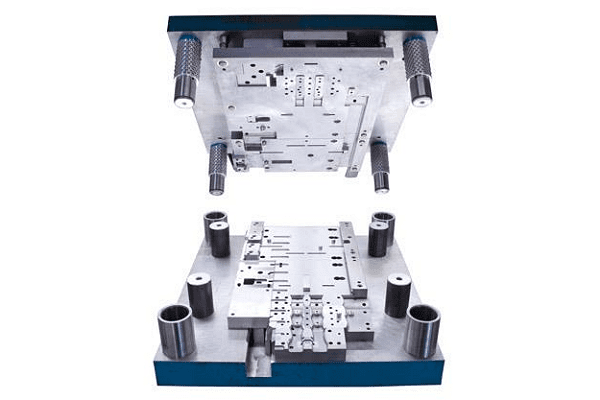

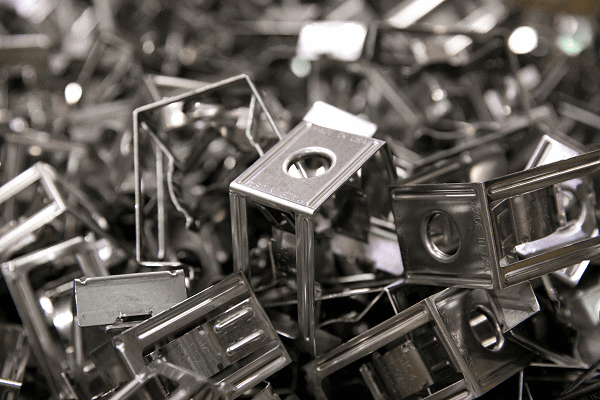

Evans Tool & Die can laser cut, brake, weld, and assemble your small-volume parts. For high-volume production, our in-house engineers and tool makers can build dies for your high-volume orders. With the help of our 67 punch presses ranging from 30 to 1,000 tons, we can produce, run, finish, package, and ship your stampings with the highest quality standards and attention to detail.

Evans Tool & Die is an ISO 9001:2015 certified, woman-owned, 75 year third-generation family business committed to making great things so our customers can build great things. Since 1948, Evans Tool & Die has continually advanced the tooling, metal stamping, machining, welding, laser cutting, and finishing processes almost every global industry depends on. To learn more about our advanced laser cutting services, request a quote or contact us.