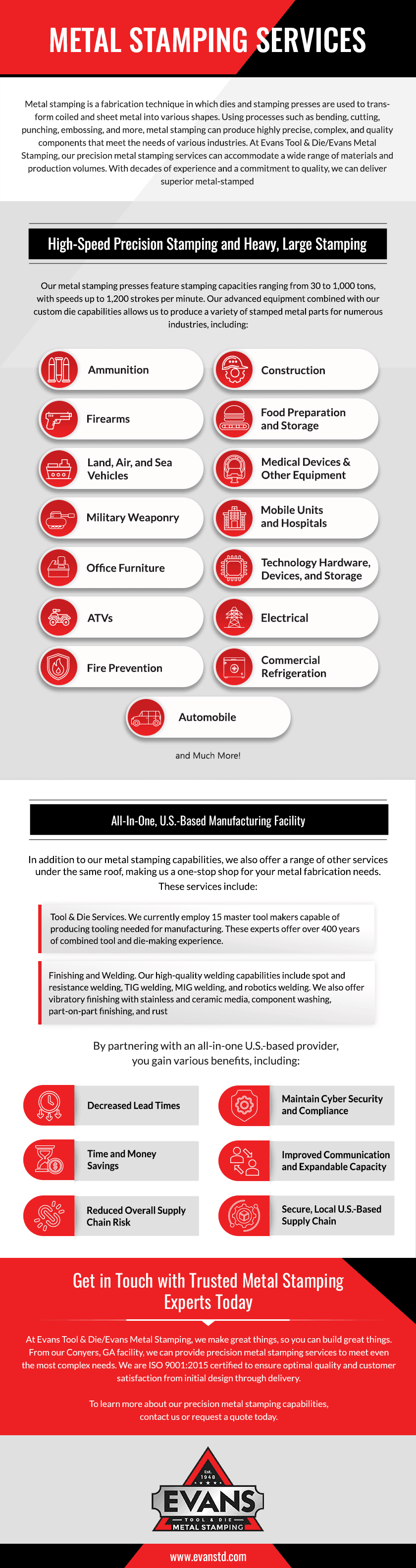

Metal Stamping Services

Metal stamping is a fabrication technique in which dies and stamping presses are used to transform coiled and sheet metal into various shapes. Using processes such as bending, cutting, punching, embossing, and more, metal stamping can produce highly precise, complex, and quality components that meet the needs of various industries. At Evans Tool & Die/Evans Metal Stamping, our precision metal stamping services can accommodate a wide range of materials and production volumes. With decades of experience and a commitment to quality, we can deliver superior metal-stamped components for our customers.

High-Speed Precision Stamping and Heavy, Large Stamping

With nearly three quarters of a century of metal stamping expertise, Evans Tool & Die/Evans Metal Stamping offers quality stamping services for everything from small, prototyping projects to high-volume production runs. To meet a range of customer needs, we can work with various metal materials, including stainless steel, aluminum, hot or cold rolled steel, coppers, brass, and Inconel. We can also handle parts that are coated, cruciform, countersunk, heat treated, embossed, or have other special features.

Our metal stamping presses feature stamping capacities ranging from 30 to 1,000 tons, with speeds up to 1,200 strokes per minute. Our advanced equipment combined with our custom die capabilities allows us to produce a variety of stamped metal parts for numerous industries, including:

- Ammunition

- Construction

- Firearms

- Food Preparation and Storage

- Land, Air, and Sea Vehicles

- Medical Devices and Other Equipment

- Military Weaponry

- Mobile Units and Hospitals

- Office Furniture

- Technology Hardware, Devices, and Storage

- ATVs

- Electrical

- Fire Prevention

- Commercial Refrigeration

- Automobile

- and Much More!

All-In-One, U.S.-Based Manufacturing Facility

In addition to our metal stamping capabilities, we also offer a range of other services under the same roof, making us a one-stop shop for your metal fabrication needs. These services include:

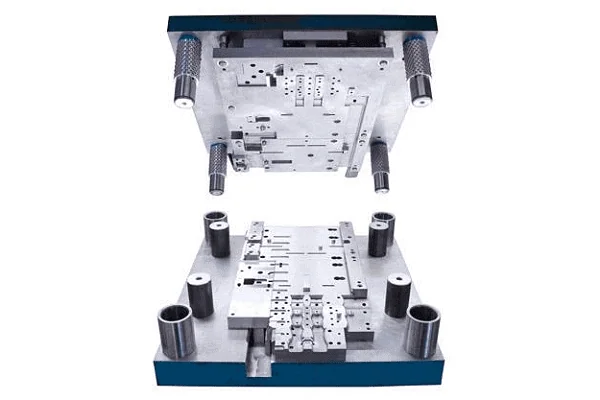

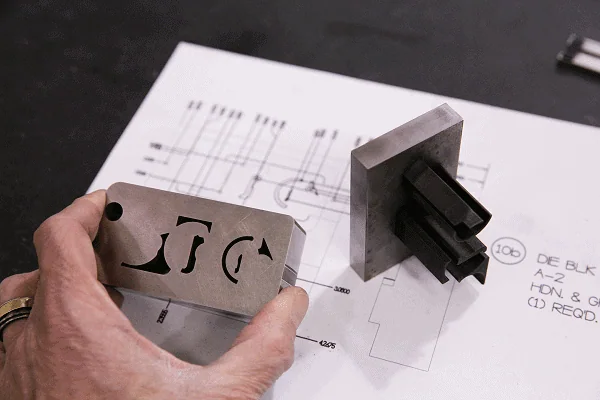

- Tool & Die Services. At Evans Tool & Die/Evans Metal Stamping, we currently employ 15 master tool makers capable of producing molds, dies, cutting tools, machine tools, and various other tools needed for manufacturing. These experts offer over 400 years of combined tool and die making experience and can offer everything from R&D and consulting to design and prototyping services.

- Finishing and Welding. Our high-quality welding capabilities include spot and resistance welding, TIG welding, MIG welding, and robotics welding. We also offer vibratory finishing with stainless and ceramic media, component washing, part-on-part finishing, and rust prevention.

By partnering with an all-in-one U.S.-based provider, you gain various benefits, including:

- Decreased Lead Times

- Time and Money Savings

- Reduced Overall Supply Chain Risk

- Maintain Cyber Security and Compliance

- Improved Communication and Expandable Capacity

- Secure, Local U.S.-Based Supply Chain

Get in Touch with Trusted Metal Stamping Experts Today

At Evans Tool & Die/Evans Metal Stamping, we make great things, so you can build great things. From our Conyers, GA facility, we can provide precision metal stamping services to meet even the most complex needs. We are ISO 9001:2015 certified to ensure optimal quality and customer satisfaction from initial design through delivery. To learn more about our precision metal stamping capabilities, contact us or request a quote today.