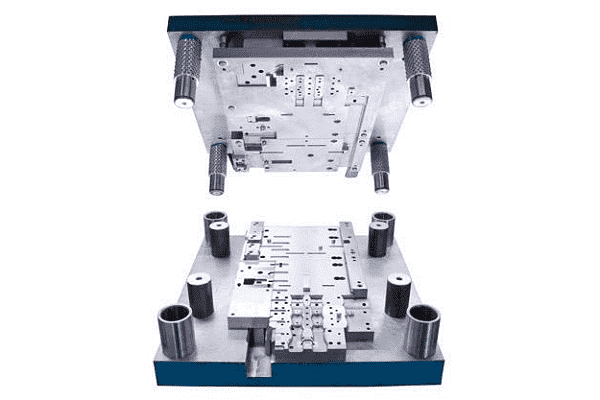

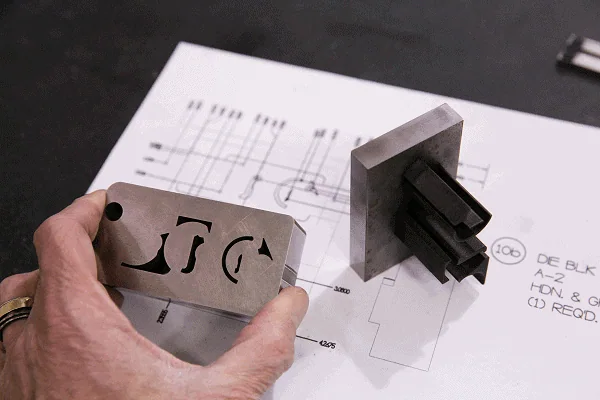

Tool & Die

We employ a deep bench of master tool makers who produce dies, molds, machine tools, cutting tools and more.

Metal Stamping

Whether large or small, single hit or progressive, we take great pride and care stamping your parts.

Laser Cutting

At Evans Tool & Die, we specialize in laser cutting a wide range of materials, including carbon and stainless steel, aluminum, and bronze.

Design Engineering

We work closely with clients to create innovative manufacturing solutions to solve our clients’ toughest engineering challenges.

What Evans Can Do For You

– Reduce Supply Chain Risk –

– Provide Efficient, Cost Saving Solutions –

– Decrease Lead Times and Time to Market –

– Deliver Excellent Products and services –

– All-In-One Made In America Provider –

Evans Tool & Die President Featured in Georgia Trend: Small Business Stars!

President & CEO Dee Barnes has been featured in Georgia Trend as a Small Business Star! Evans Tool & Die is featured as one of the small businesses leading the charge post-COVID to help the surge in Made in America manufacturing. Georgia is ranked as the Top State for Business, offering a thriving environment for […]

> Read More

Woman Owned Small Business

Our Certifications

ISO 9001:2015 - QUALITY

Evans has earned and maintains our ISO certification for excellence in manufacturing quality.

National Association of Manufacturers

Evans Tool & Die is a proud member of the National Association of Manufacturers.

Georgia Made

Evans Tool & Die's products are Made in Georgia.