Benefits of Modern Progressive Metal Stamping and Hand Transfer Stamping in Manufacturing

Metal stamping is a type of metal working that has been around for decades. It involves shaping various metals into specific shapes or parts through multiple stages of compressive deformation. The stamping process works by applying an external force over a single work piece or metal sheet which can be made up of different alloys, each having their own degree of malleability.

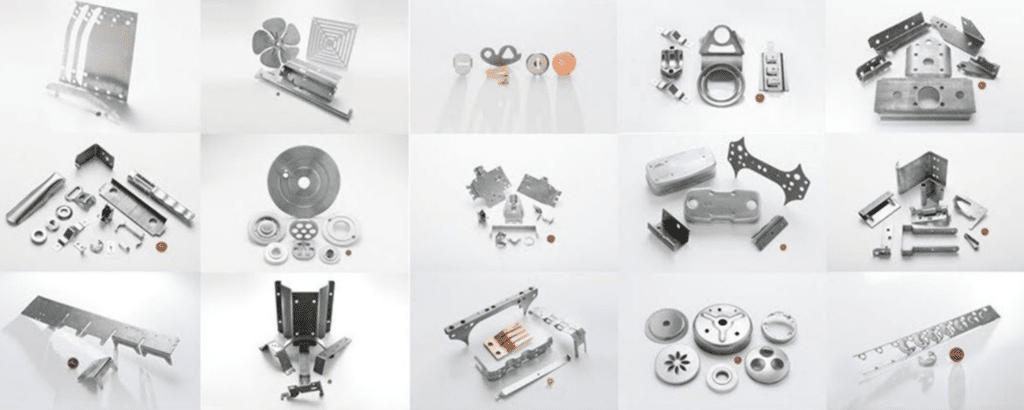

Various types of metal stamping materials can be used in order to produce stamped metal parts and goods with greater strength, durability, mass-proportion, and performance without changing the weight significantly.

Stamped metal parts play a major role in today’s manufacturing

Products produced by metal stamping companies like Evans Metal Stamping, Inc are part of virtually every part of our lives where metal parts are used. From medical supply tooling to construction tools to decorative emblems and major structural components in automobile manufacturing… Metal stamping plays a major role in production.

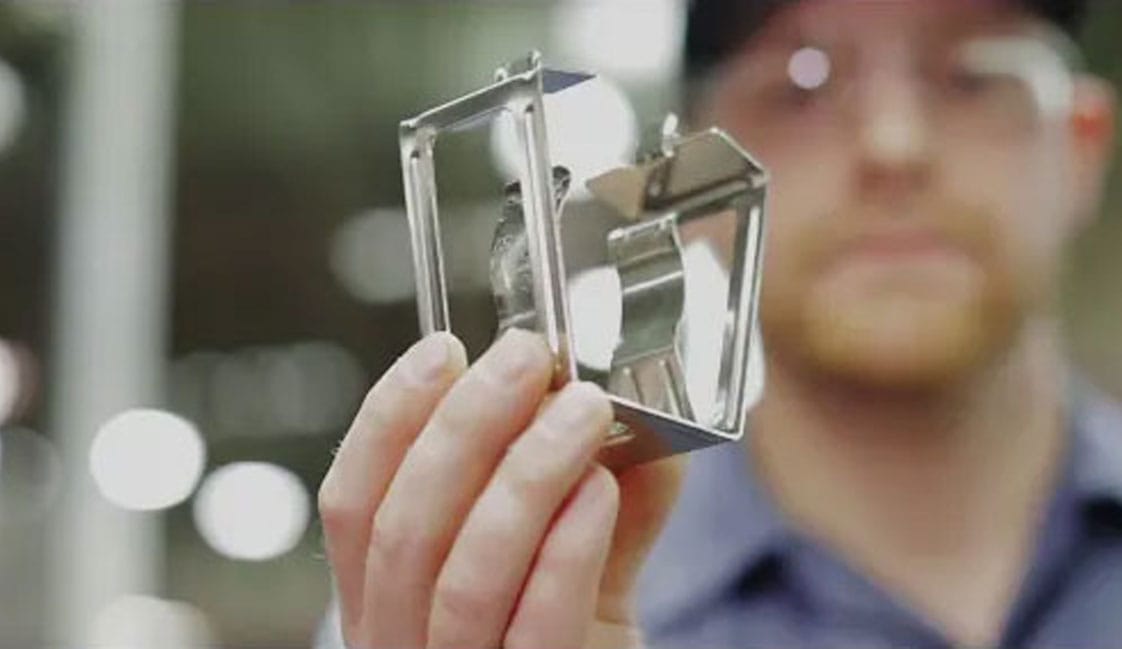

Manufacturing has become highly specialized with the evolution of various techniques, advanced stamping presses and different materials used for stamping. By using the finest metals available for stamping, manufacturers can provide customers with high quality products in mass quantities and in a timely manner.

Most common types of metal stamping used when stamping products

The two most commonly used techniques used in modern day manufacturing are progressive die metal stamping and transfer die stamping. Both of these techniques have specific processes that make them unique. Depending on the size of stamped work piece, complexity, material and quantity needed, the manufacturer decides which technique to use.

The progressive stamping process at Evans Tool & Die

Progressive metal stamping is a manufacturing process involving the progressive deformation of an object by successively applying compressive force. It has also been known to be referred to as progressive die sinking and owes its name to the fact that it involves a series of dies (some would call them punches) which, through successive action, progressively form the product.

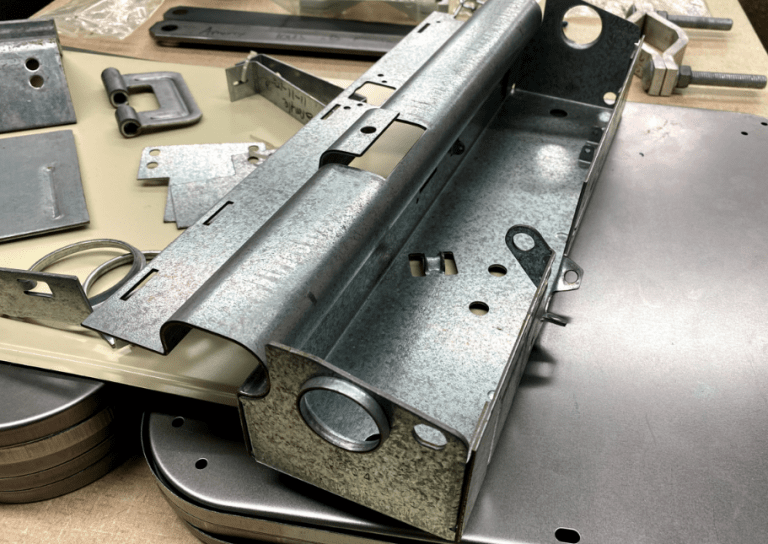

Stamping can necessitate low and high tonnage presses, using significant energy and large or small dies. The products are usually made from metal rolled up on heavy coils . The coiled metal is fed through the punch press and the part is stamped in progressive stages through the die that is bolted into the press. Progressive stamping will produce a significantly higher volume of parts at a much faster rate than hand transfer stamping.

At Evans Metal Stamping, Inc, we can assist with prototyping or run high volume jobs. Our metal presses can handle 30 to 1,000 tons at speeds up to 1,200 cycles per minute. When your project calls for high quality, precision stamping, Evans can handle your project no matter how big or time sensitive it may be.

Our capabilities in producing precision, high quality and high-volume runs are due to the state of the art machinery we use and our highly trained and experienced technicians. Our stamping machinery includes but is not limited to:

- 39 conventional presses from 30 to 1000 ton

- 27 high speed (1200 SPM) Bruderer presses from 40 to 125 ton

- 6 brake presses from 150 to 250 ton

- 3 shears

Hand transfer metal stamping

Hand transfer metal stamping is used to place individual pieces or parts of the design onto sheet metal, or stamp more heavy-duty single hit designs. Transfer die stamping is similar to progressive die stamping, but the part is free from the metal strip. Hand transfer metal stamping can also be used to add detail into already existing designs or produce larger components such as industrial generator pans which may require moving the workpiece from die to multiple dies.

Hand transfer metal stamping has been around for centuries and still used today by metal fabricators all over the world.

Evans has the capacity to produce high volumes of industrial type metal parts due to our decades of experience and machinery used to produce the parts.

Evans Metal Stamping is proudly made and produced in the USA

Evans is a one-stop shop, made in the USA, Preferred Provider of precision Tool & Die builds and progressive and hand transfer metal stamping products. We provide complete design and engineering processes, assembly, and packaging. We provide risk management solutions to the overseas supply chain breakdowns for OEMs by localizing supply chains with high quality, seamless logistics and hands on supply chain control.

Contact Evans today to discuss your upcoming project: (770) 922-3480