What Is a Tool and Die Maker?

Tool and die makers are an incredible asset for any manufacturing facility. They excel at the top of the metalworking trades, with their mechanical aptitude allowing them to create parts and machines requiring high precision. Moreover, these experts can independently design and construct tools without requiring managerial oversight or instruction. The highest skill level is a “master toolmaker,” which takes 5-10 years of apprenticeship and hands-on experience.

Responsibilities of a Tool and Die Maker

A tool and die maker is responsible for designing and fabricating tools, dies, and other metalworking equipment. Thus, they must understand metalworking processes, mathematics, physics, engineering principles, and computerized machining to create these tools with extreme precision. Additionally, they must be able to accurately read blueprints and designs to reproduce them as closely as possible.

Here are some of the specific tasks of a tool and die maker:

- Fabricate specialized tools and dies to craft fixtures and construct new gears whenever needed.

- Troubleshoot and repair dies, molds, tools, jigs, fixtures, and other components as required. Safely dismantle parts, then put them back together after a successful repair.

- Possess the capacity to comprehend and interpret blueprints and intricate schematics to manufacture tools, fixtures, and machine parts.

- Utilize computer-aided design (CAD) software to develop innovative designs and transform them into blueprints.

- Thoroughly examine finished tools and dies for marks of defect or wear that might hinder performance.

- Guarantee that all equipment, tools, and machines are functioning optimally. Regularly inspect them for proper configuration.

- Customize machines to precisely adjust speed, material feed, and cut paths for maximum quality assurance to produce a product that meets specifications.

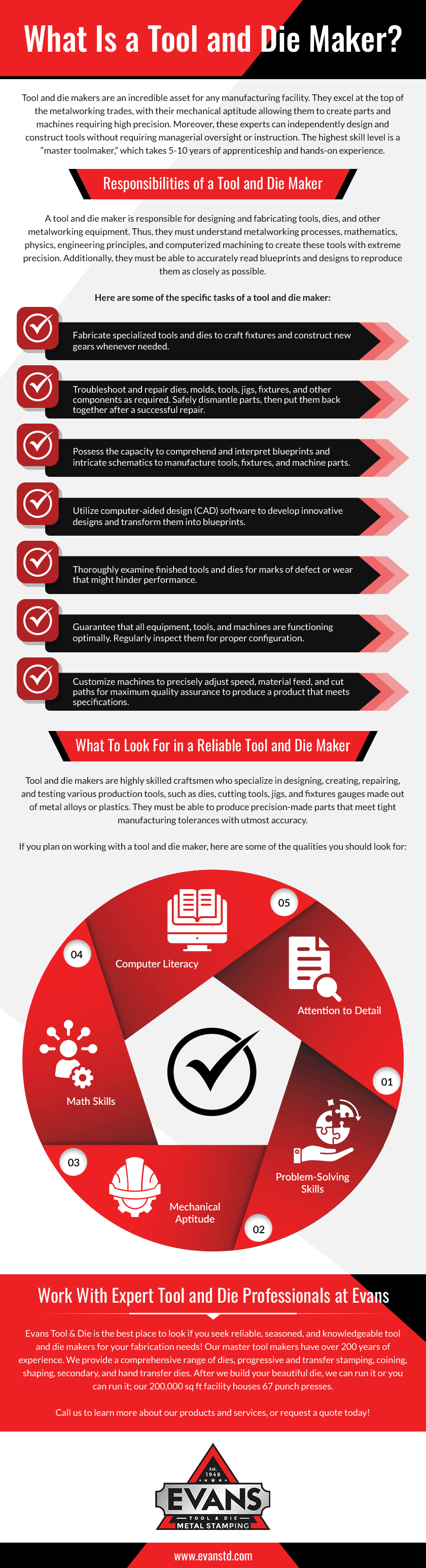

What To Look For in a Reliable Tool and Die Maker

Tool and die makers are highly skilled craftsmen who specialize in designing, creating, repairing, and testing various production tools, such as dies, cutting tools, jigs, and fixtures gauges made out of metal alloys or plastics. They must be able to produce precision-made parts that meet tight manufacturing tolerances with utmost accuracy.

If you plan on working with a tool and die maker, here are some of the qualities you should look for:

Attention to Detail

Tool and die makers need to pay close attention to detail to ensure accuracy in their work. They must also focus on the task without becoming sidetracked, especially when dealing with complex requirements.

Problem-Solving Skills

Strong problem-solving skills are a must-have for tool and die makers. This will help them determine why a particular machine or tool isn’t functioning correctly.

Mechanical Aptitude

Mechanics are integral when designing, constructing, and repairing tools and dies. Therefore, a solid understanding of this field is essential for success as a tool and die maker.

Math Skills

Tool and die makers must have strong math skills since they often need to convert measurements from one unit of length to another when creating their tools. They also need to be able to read blueprints to ensure that the finished product meets all specified requirements accurately.

Computer Literacy

Being familiar with CAD software is key for tool and die makers since it is increasingly becoming more common in modern factories and manufacturing processes.

Work With Expert Tool and Die Professionals at Evans

Evans Tool & Die is the best place to look if you seek reliable, seasoned, and knowledgeable tool and die makers for your fabrication needs! Our master tool makers have over 200 years of experience. We provide a comprehensive range of dies, progressive and transfer stamping, coining, shaping, secondary, and hand transfer dies. After we build your beautiful die, we can run it or you can run it; our 200,000 sq ft facility houses 67 punch presses.

Call us to learn more about our products and services, or request a quote today!