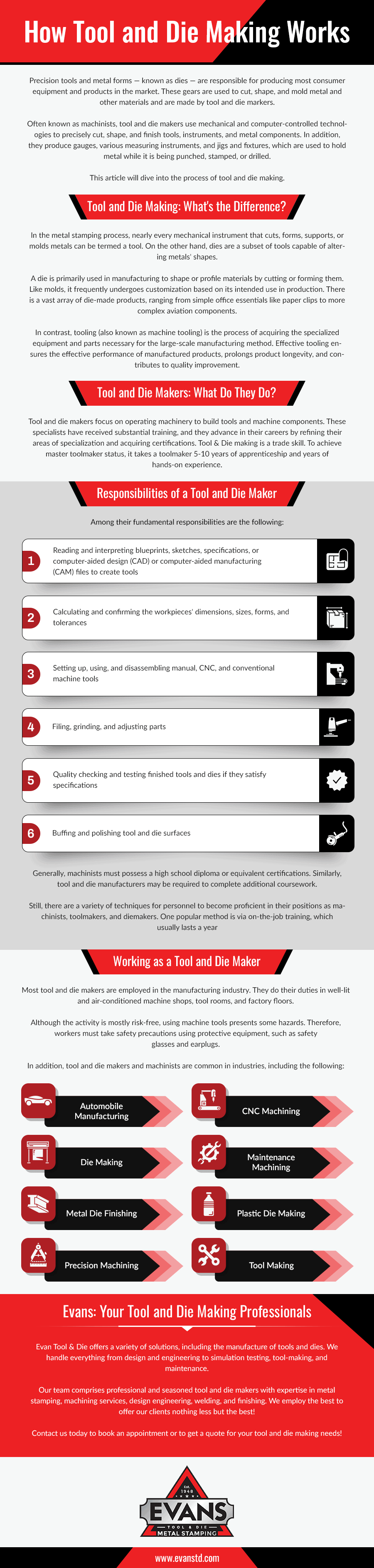

How Tool and Die Making Works

Precision tools and metal forms — known as dies — are responsible for producing most consumer equipment and products in the market. These gears are used to cut, shape, and mold metal and other materials and are made by tool and die markers.

Often known as machinists, tool and die makers use mechanical and computer-controlled technologies to precisely cut, shape, and finish tools, instruments, and metal components. In addition, they produce gauges, various measuring instruments, and jigs and fixtures, which are used to hold metal while it is being punched, stamped, or drilled.

This article will dive into the process of tool and die making.

Tool and Die Making: What’s the Difference?

In the metal stamping process, nearly every mechanical instrument that cuts, forms, supports, or molds metals can be termed a tool. On the other hand, dies are a subset of tools capable of altering metals’ shapes.

A die is primarily used in manufacturing to shape or profile materials by cutting or forming them. Like molds, it frequently undergoes customization based on its intended use in production. There is a vast array of die-made products, ranging from simple office essentials like paper clips to more complex aviation components.

In contrast, tooling (also known as machine tooling) is the process of acquiring the specialized equipment and parts necessary for the large-scale manufacturing method. Effective tooling ensures the effective performance of manufactured products, prolongs product longevity, and contributes to quality improvement.

Tool and Die Makers: What Do They Do?

Tool and die makers focus on operating machinery to build tools and machine components. These specialists have received substantial training, and they advance in their careers by refining their areas of specialization and acquiring certifications. Tool & Die making is a trade skill. To achieve master toolmaker status, it takes a toolmaker 5-10 years of apprenticeship and years of hands-on experience.

Responsibilities of a Tool and Die Maker

Among their fundamental responsibilities are the following:

- Reading and interpreting blueprints, sketches, specifications, or computer-aided design (CAD) or computer-aided manufacturing (CAM) files to create tools and dies

- Calculating and confirming the workpieces’ dimensions, sizes, forms, and tolerances

- Setting up, using, and disassembling manual, CNC, and conventional machine tools

- Filing, grinding, and adjusting parts

- Quality checking and testing finished tools and dies if they satisfy specifications

- Buffing and polishing tool and die surfaces

Generally, machinists must possess a high school diploma or equivalent certifications. Similarly, tool and die manufacturers may be required to complete additional coursework.

Still, there are a variety of techniques for personnel to become proficient in their positions as machinists, toolmakers, and diemakers. One popular method is via on-the-job training, which usually lasts a year.

Working as a Tool and Die Maker

Most tool and die makers are employed in the manufacturing industry. They do their duties in well-lit and air-conditioned machine shops, tool rooms, and factory floors.

Although the activity is mostly risk-free, using machine tools presents some hazards. Therefore, workers must take safety precautions using protective equipment, such as safety glasses and earplugs.

In addition, tool and die makers and machinists are common in industries, including the following:

- Automobile manufacturing

- CNC machining

- Die making

- Maintenance machining

- Metal die finishing

- Plastic die making

- Precision machining

- Tool making

Evans: Your Tool and Die Making Professionals

Evan Tool & Die offers a variety of solutions, including the manufacture of tools and dies. We handle everything from design and engineering to simulation testing, tool-making, and maintenance.

Our team comprises professional and seasoned tool and die makers with expertise in metal stamping, machining services, design engineering, welding, and finishing. We employ the best to offer our clients nothing less but the best!

Contact us today to book an appointment or to get a quote for your tool and die making needs!