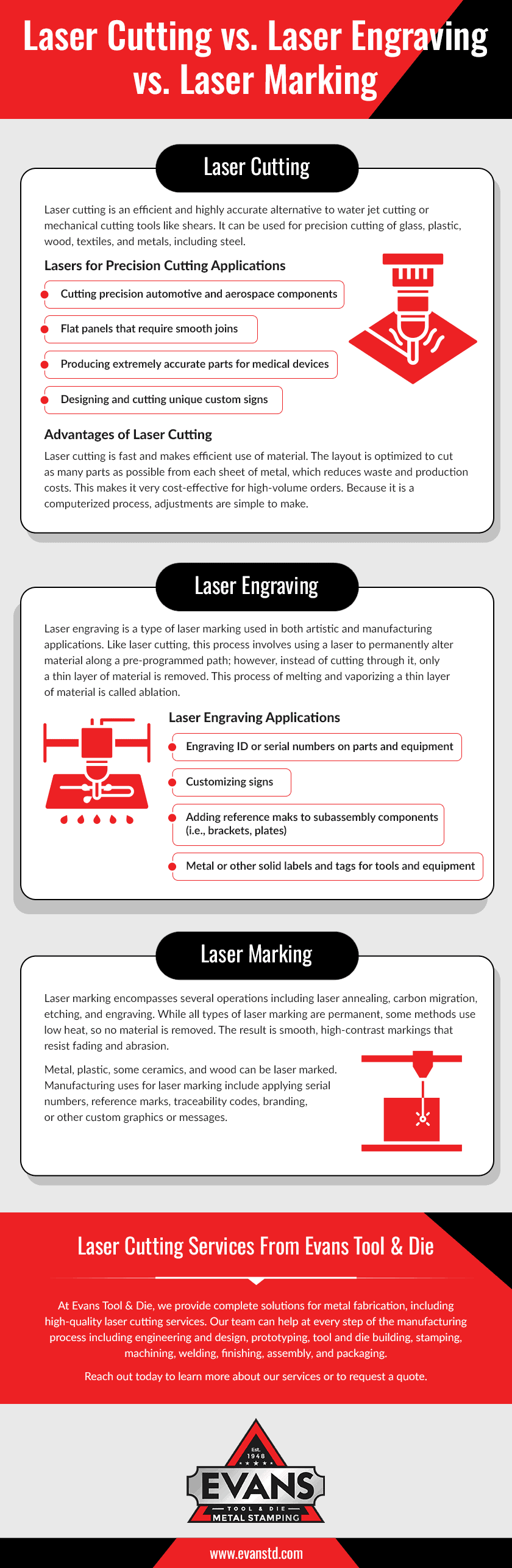

Laser Cutting vs. Laser Engraving vs. Laser Marking: Understanding the Differences

A laser is a highly focused beam of light that emits a specific wavelength and heat. A system of mirrors and lenses in the laser machine guides and concentrates the beam into a predetermined focal point. Heat given off by the laser hits a material substrate to permanently alter it, by marking or etching its surface, or by cutting through it completely.

Depending on the type of laser (i.e., CO2, fiber, etc.), its wavelength, and the power level, lasers can be used for many creative purposes, commercial products, and manufacturing processes including welding, cutting, etching, annealing, and more.

Here we’ll look at the differences between laser cutting, engraving, and marking operations.

Laser Cutting

Laser cutting is an efficient and highly accurate alternative to water jet cutting or mechanical cutting tools like shears. It can be used for precision cutting of glass, plastic, wood, textiles, and metals, including steel.

The laser beam is focused and guided by a system of optical components inside the laser machine, directing the beam to a point on the material. Heat from the laser melts the material enough to burn or melt through it. Different materials require different types and strengths of lasers. For example, a powerful CO2 laser is required to cut through steel.

After making an initial puncture in the material, the beam is moved according to the desired pattern and cuts a path. Laser cutting machines are controlled by computerized motion control systems that use G-code programming to create specific cuts, features, and shapes. Laser cuts can be simple or intricate. A laser can also be used to drill holes with great precision.

Lasers for Precision Cutting Applications

Laser cutting is used in many manufacturing applications. Some examples include:

- Cutting precision automotive and aerospace components

- Flat panels that require smooth joins

- Producing extremely accurate parts for medical devices

- Designing and cutting unique custom signs

Advantages of Laser Cutting

Laser cutting is fast and makes efficient use of material. The layout is optimized to cut as many parts as possible from each sheet of metal, which reduces waste and production costs. This makes it very cost-effective for high-volume orders. Because it is a computerized process, adjustments are simple to make.

The beam can be focused on a highly concentrated and tiny focal point, and exact coordinates are programmed into the machine, so it’s possible to achieve extremely tight tolerances for cuts and shapes. As non-contact tools, lasers don’t leave stray marks, scorch, or otherwise damage material outside of designated areas on the workpiece. What’s more, because the material is melted and vaporized, cuts and holes are usually smooth and clean, requiring little to no additional finishing.

Laser Engraving

Laser engraving is a type of laser marking used in both artistic and manufacturing applications. Like laser cutting, this process involves using a laser to permanently alter material along a pre-programmed path; however, instead of cutting through it, only a thin layer of material is removed. This process of melting and vaporizing a thin layer of material is called ablation.

Solid state fiber lasers are often used for engraving. Materials including metal, stone, brick, wood, acrylic, fabric, and cardboard can be laser engraved. Depending on the wavelength and other parameters, engravings can be raised, shallow, or deep. Most engravings are between .0001 in. and .005 in. deep.

Laser engraving applications

This process is used for applications including:

- Engraving ID or serial numbers on parts and equipment

- Customizing signs

- Adding reference maks to subassembly components (i.e., brackets, plates)

- Metal or other solid labels and tags for tools and equipment

Laser Marking

Laser marking encompasses several operations including laser annealing, carbon migration, etching, and engraving. While all types of laser marking are permanent, some methods use low heat, so no material is removed. The result is smooth, high-contrast markings that resist fading and abrasion.

Metal, plastic, some ceramics, and wood can be laser marked. Manufacturing uses for laser marking include applying serial numbers, reference marks, traceability codes, branding, or other custom graphics or messages.

Laser Cutting Services From Evans Tool & Die

At Evans Tool & Die, we provide complete solutions for metal fabrication, including high-quality laser cutting services. Our team can help at every step of the manufacturing process including engineering and design, prototyping, tool and die building, stamping, machining, welding, finishing, assembly, and packaging.

Reach out today to learn more about our services or to request a quote.