What are the Different Types of Laser Cutting?

Industrial laser cutting quickly produces uniform metal components that require minimal finishing. It is commonly used with metals and alloy metals, as well as ceramics, some plastics, glass, and textiles in different thicknesses. Lasers can also be used for engraving, annealing, and other operations.

Here, we’ll look at how laser cutting works and present four common types of lasers used in industry. We’ll also look at some typical laser cutting applications.

What Is Laser Cutting?

“Laser” is an acronym for Light Amplification by Stimulated Emission of Radiation. Essentially, the laser cutting process involves the use of concentrated beams of light to cut, melt, and vaporize material. This process is suitable for cutting materials in various thicknesses and can be used to create both simple and complex shapes.

Laser beams are generated when electrons in optical materials like crystal, gas, or glass absorb energy from light or an electric current. The excited electrons emit light energy, which is then directed through material that amplifies it. Lasers are also “doped” with different elements to produce desired wavelengths.

Because it is a non-contact process, laser cutting will not scorch, scratch, or leave tool marks on workpieces. Cuts are clean, with no burrs or rough edges; therefore, they require little to no additional finishing such as deburring or grinding.

What Are the Different Types of Laser Cutting?

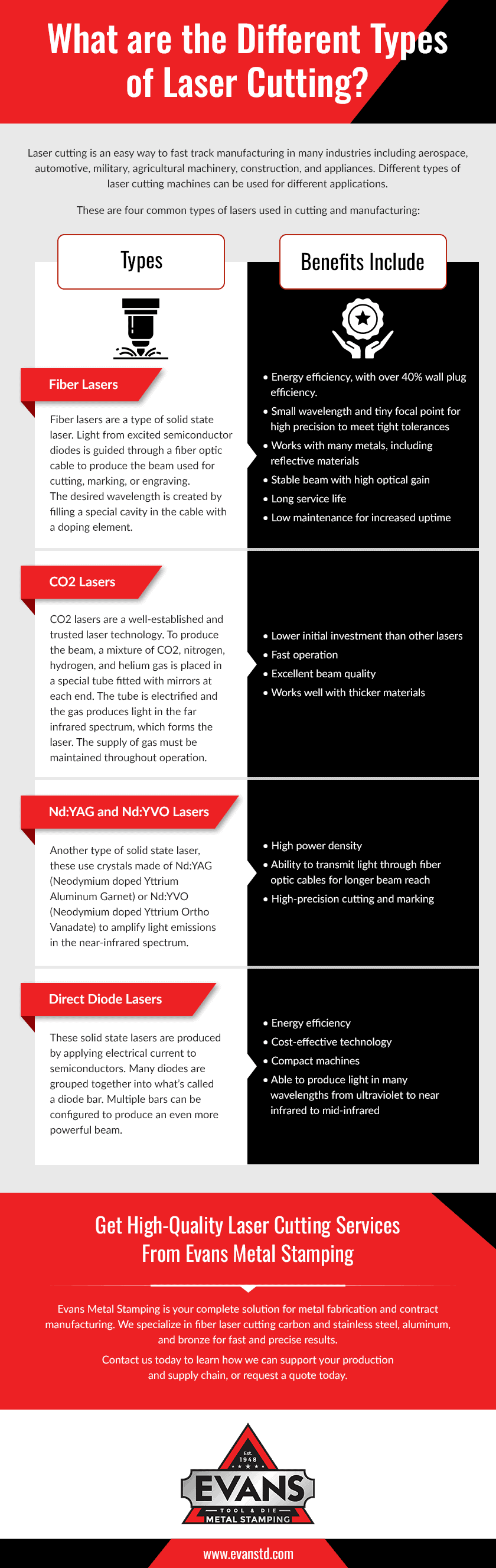

Laser cutting is an easy way to fast track manufacturing in many industries including aerospace, automotive, military, agricultural machinery, construction, and appliances. Different types of laser cutting machines can be used for different applications.

These are four common types of lasers used in cutting and manufacturing:

Fiber Laser Cutting

Fiber lasers are a type of solid-state laser. Light from excited semiconductor diodes is guided through a fiber optic cable to produce the beam used for cutting, marking, or engraving. The desired wavelength is created by filling a special cavity in the cable with a doping element.

Benefits include:

- Energy efficiency, with over 40% wall plug efficiency

- Small wavelength and tiny focal point for high precision to meet tight tolerances

- Works with many metals, including reflective materials

- Stable beam with high optical gain

- Long service life

- Low maintenance for increased uptime

Fiber lasers are well-suited for thinner materials. They are often used for marking, annealing, engraving, cutting, and welding. Common materials used with fiber lasers include metal, glass, ceramics, composite polymers, and plastics.

CO2 Laser Cutting

CO2 lasers are a well-established and trusted laser technology. To produce the beam, a mixture of CO2, nitrogen, hydrogen, and helium gas is placed in a special tube fitted with mirrors at each end. The tube is electrified and the gas produces light in the far infrared spectrum, which forms the laser. The supply of gas must be maintained throughout operation.

Benefits include:

- Lower initial investment than other lasers

- Fast operation

- Excellent beam quality

- Works well with thicker materials

CO2 lasers are often used with non-metals including paper and wood. They can also be used with acrylics, leather, textiles, and food products, as well as for cutting different steel materials.

Nd:YAG and Nd:YVO Laser Cutting

Another type of solid state laser, these use crystals made of Nd:YAG (Neodymium doped Yttrium Aluminum Garnet) or Nd:YVO (Neodymium doped Yttrium Ortho Vanadate) to amplify light emissions in the near-infrared spectrum.

Benefits include:

- High power density

- Ability to transmit light through fiber optic cables for longer beam reach

- High-precision cutting and marking

Nd:YAG and Nd:YVO lasers are frequently used for aerospace and other applications that use titanium, nickel, and steel. They are also used to mark and engrave very hard materials including polycarbonates and ceramics.

Direct Diode Laser Cutting

These solid state lasers are produced by applying electrical current to semiconductors. Many diodes are grouped together into what’s called a diode bar. Multiple bars can be configured to produce an even more powerful beam.

Benefits include:

- Energy efficiency

- Cost-effective technology

- Compact machines

- Able to produce light in many wavelengths from ultraviolet to near infrared to mid-infrared

Diode lasers can weld, cut, and mark sheets of steel and aluminum, as well as polymethylmethacrylate and polycarbonate. There may be limits on the thickness of materials that can be cut with a diode laser.

Get High-Quality Laser Cutting Services From Evans Metal Stamping

Evans Metal Stamping is your complete solution for metal fabrication, such as metal stamping and fiber laser cutting carbon and stainless steel, aluminum, and bronze for fast and precise results.

Contact us today to learn how we can support your production and supply chain, or request a quote today.