How Laser Cutting is Used in the Defense Industry

The military and defense industry relies on mission-critical equipment and vehicles for ground, air, and water-based operations. The parts and assemblies that go into everything from trucks and transport aircraft to satellite equipment must be manufactured on time and without errors to meet MIL-SPEC and performance requirements.

Laser cutting is a manufacturing process used often for military and defense-related applications. It is highly accurate and repeatable for making parts with tight tolerances at high volumes. Laser cutting machines can also be used with a range of materials.

Here, we’ll look at some military and defense applications for laser cutting, general material options, and the advantages this technology offers.

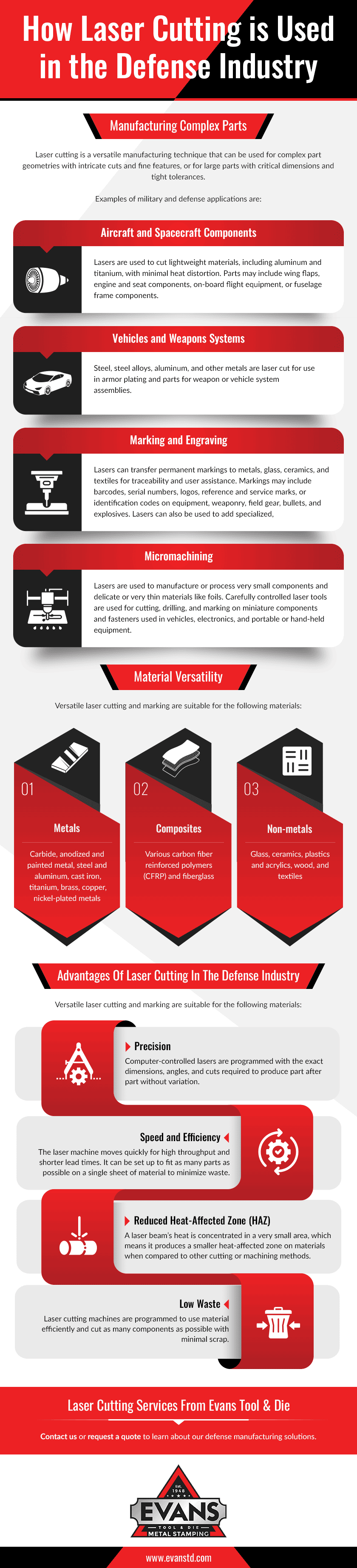

Manufacturing Complex Parts

Laser cutting is a versatile manufacturing technique that can be used for complex part geometries with intricate cuts and fine features, or for large parts with critical dimensions and tight tolerances.

Examples of military and defense applications are:

- Aircraft and spacecraft components. Lasers are used to cut lightweight materials, including aluminum and titanium, with minimal heat distortion. Parts may include wing flaps, engine and seat components, on-board flight equipment, or fuselage frame components.

- Vehicles and weapons systems. Steel, steel alloys, aluminum, and other metals are laser cut for use in armor plating and parts for weapon or vehicle system assemblies.

- Marking and engraving. Lasers can transfer permanent markings to metals, glass, ceramics, and textiles for traceability and user assistance. Markings may include barcodes, serial numbers, logos, reference and service marks, or identification codes on equipment, weaponry, field gear, bullets, and explosives. Lasers can also be used to add specialized, high-performance textures.

- Micromachining. Lasers are used to manufacture or process very small components and delicate or very thin materials like foils. Carefully controlled laser tools are used for cutting, drilling, and marking on miniature components and fasteners used in vehicles, electronics, and portable or hand-held equipment.

Material Versatility

Defense and military parts, gear, and equipment contain many different types of materials including metals, non-metals, and textiles. Lasers are capable of marking, embossing, and cutting substrates in a range of thicknesses. Depending on the application, both fiber and CO2 lasers give excellent cutting and marking results.

Versatile laser cutting and marking are suitable for the following materials:

- Metals: Carbide, anodized and painted metal, steel and aluminum, cast iron, titanium, brass, copper, nickel-plated metals

- Composites: Various carbon fiber reinforced polymers (CFRP) and fiberglass

- Non-metals: Glass, ceramics, plastics and acrylics, wood, and textiles

Advantages Of Laser Cutting In The Defense Industry

Equipment and devices used in military and defense operations must be well-made and reliable. That means the parts, assemblies, and subassemblies that go into them must also meet strict specifications and tolerances so they fit and function correctly. Laser cutting, marking, and processing excel at meeting this goal.

Laser cutting offers these advantages for military manufacturing:

- Precision. Computer-controlled lasers are programmed with the exact dimensions, angles, and cuts required to produce part after part without variation. Lasers also leave no tool marks or gouges on surfaces, which can affect tolerances or performance.

- Speed and efficiency. The laser machine moves quickly for high throughput and shorter lead times. It can be set up to fit as many parts as possible on a single sheet of material to minimize waste. Lasers generate sufficient power to melt or vaporize the material so cuts, holes, and markings have no rough edges and need no extra finishing, like deburring or sanding.

- Reduced heat-affected zone (HAZ). A laser beam’s heat is concentrated in a very small area, which means it produces a smaller heat-affected zone on materials when compared to other cutting or machining methods. A smaller HAZ results in less distortion at the edges and does not compromise the structural integrity of the material.

- Low waste. Laser cutting machines are programmed to use material efficiently and cut as many components as possible with minimal scrap. The material is carefully aligned on the cutting bed so all cuts are extremely accurate with very few errors. Integrated vision systems and cameras can also be used to monitor and adjust the laser’s path on the fly.

Laser Cutting Services From Evans Tool & Die

Evans Tool & Die provides laser cutting services for precision components in the military and defense industry, and more. We also offer military metal stamping services, metal fabrication, welding, electroplating, and finishing services for a complete solution to your manufacturing needs.

We are a family-owned and operated business and have been committed to integrity, quality, and accountability in our work since 1948. Our team serves the Conyers, GA area and beyond.

Contact us or request a quote to learn about our defense manufacturing solutions.