The Challenge of Design and Engineering

There is often a disconnect between design and engineering. To illustrate that point, consider an architect who designs amazing buildings that are more beautiful than our wildest dreams! But can those buildings actually be built? The same situation happens all the time in the manufacturing process. That is the challenge of design and engineering. At Evans, we don’t design your parts. We make them, and we help you make your parts better, stronger, and manufacture them more efficiently. Here is a case study of how we did exactly that for Textron Specialized Vehicles, the maker of golf carts and ATVs.

It Can’t Be Made

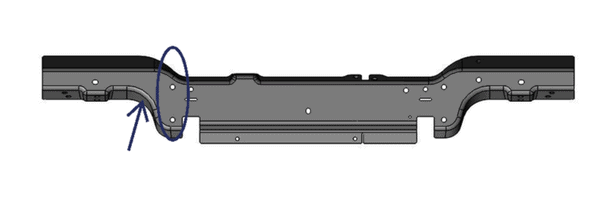

Back in 2015, Evans Design Engineer Randall Stanfield received a request for a quote to produce a specific part. The note that he added to the initial design drawing read, “We cannot make this product as designed.” And that design was version 8 of the design drawing. The part was a grade 50 stamped steel part for an ATV / Golf cart. This model was a brand new product for Textron, and this was their first entry (3 years ago) in the ATV market.

When Evans was invited to bid on several parts, we did not want to make this particular part simply because it could not be built as designed. So, we bid on it, but with a prohibitively high cost so as to make sure that we did not win the bid. Unfortunately, so did everyone else! So, they invited us to consult on the design and engineering of the part. It was during that consultative process that we worked together to figure out the best way to design the part so that it could actually be manufactured.

Design vs. Reality

When designing a part, you need to know whether or not it can actually be made. You can only know that by experience and repetition. Engineering school provides a future engineer a great foundation, but school cannot provide real world experience. Experience brings to life the large delta between design and reality, much like your house in the architect’s drawing: everything is perfectly square and level, but when you put it together, it’s not perfectly square or perfectly level. That’s reality. It is the same with a stamped metal part. So in the end, you may have to “change the print” (the design) to match the part that can actually be manufactured.

“Sometimes, we work with the manufacturer (customer) to modify the design to match the part we create, so the end product can be produced,” said Stanfield. “That’s exactly what we did for Textron.”

Eight Months & 19 Design Revisions

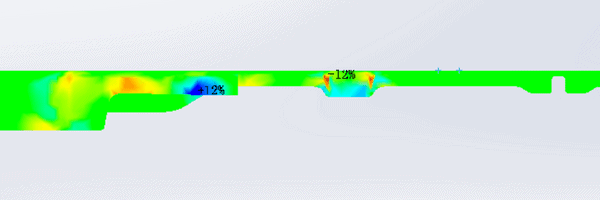

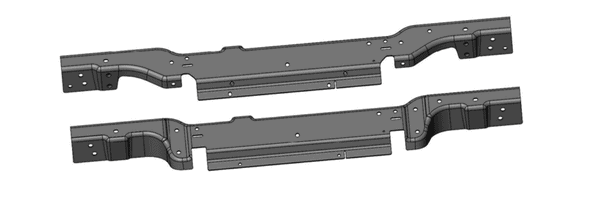

Design revision 8, the first design drawing we received, when tested on LogoPress, got 60% thin-out on the turns and bends in the steel. The steel could only withstand 20% thin-out. We redesigned the part, and got it down to 12% thin-out based on what the metal could do, rather than what the ATV required as designed. Eight months and 19 design and engineering revisions later, we produced version 27 of the design drawing. Evans is still producing that same part today.

Technology Makes Us Faster

Ten years ago, it would have taken us more than 3 years to get to revision 27. Using such advanced testing software shortened that time to just 8 months. The LogoPress software enables us to do detailed design calculations to determine very closely the actual tolerances of the stamped metal part before we actually physically build the part. Before the software, we built the part, then hit it (literally) to see where it would break. This particular part would have required dozens or hundreds of rebuilds.

Update the Product Design

Regardless of how long the process takes, there will always be changes to the design. Therefore, the final design drawings will need to be changed to match the final successful manufactured part. If the customer engineer does not change the final drawing to match the final part specs, in the future, someone’s going to say, “We can’t accept that! It doesn’t match the specification!”

How Can We Go Even Faster?

Design and engineering in manufacturing are, by their very nature, iterative processes. It takes time. Nobody is going to design the perfectly manufactured part in the first revision. How could we shorten the manufacturing design and engineering process? The best method for designing manufactured parts is to get the toolmaker involved early in the process. Let the manufacturing engineers talk to the design engineers. The engineers can discuss actual math, physics, tolerances, and final approval.

This entry was posted in Capabilities, Examples and tagged design, engineering, logopress. Bookmark the permalink.